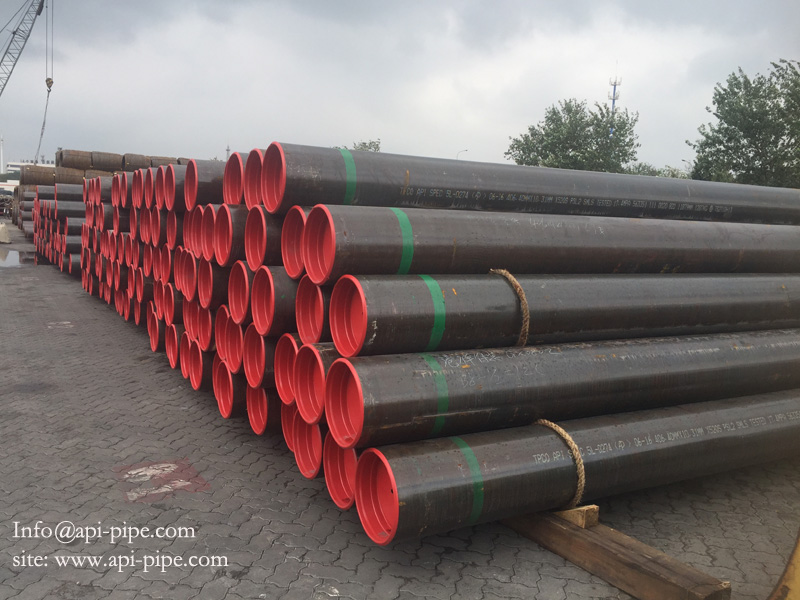

OCTG casing and tubing is a kind of popular steel pipe in the steel industry, but there occurs decarburization phenomenon for the OCTG tubing and casing. Then what do we take the measures to avoid decarburization for them?

Once OCTG casing and tubing decarburization in the process of production will affect the follow-up process and also reduce the excellent performance and service life of casing and tubing in the project. Therefore, manufacturers usually take proper steps to avoid or solve this problem to protect casing and tubing.

OCTG Casing and Tubing

Generally, there are two ways to avoid decarburization. One is the common and simple way: make full use of nitrogen protective to sustain the pressure inside the furnace. According to proportion, workers can join or inject into the neutral nitrogen to the furnace, which will not only prevent the outside air decomposing into oxygen and water vapor into the debris but also disperse the gas existing oxidation in furnace effectively. Without reaction medium with the surface of carbon, decarburization would not happen and the area of the decarburization also can be reduced generally.

Another way is to make the balance to control furnace carbon dioxide levels according to the workpiece. Expert research if the balance in the furnace is higher than the content of carbon dioxide and other gases, there will be no decarburization and oxidation phenomenon; If carbon dioxide is equal to balance, there will show the results of the neutral without decarburization and oxidation; the final result is the main cause of decarburization, that is the oxidation furnace gas content is higher than balance. So if you want to avoid the decarburization phenomenon, you must calculate the balance point according to the internal temperature and carbon content of workpiece; then control the content of oxidizing gases in the furnace.