Specifications about API 5CT Well Casing

★Standard: API SPEC 5CT

★Grades: J55, K55, N80-1, N80-Q, L80-1, L80-9Cr, L80-13Cr, C95, P110, Q125

★Dimensions: OD: 114.3-508mm WT: 5.21-16.13mm

★Thread types: STC, LTC, BTC, special clearance, XC, VAM TOP, NEW VAM.

★Applications: oil well casing serves as well sidewall.

API SPEC 5CT well casing is utilized in fixing the well wall or down hole, which has wider diameters. API SPEC 5CT can be divided into conductor casing, technical casing and oil casing.

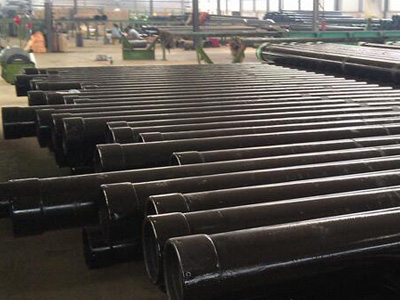

Oil Well Casing Workshop

Oil Well Casing Workshop API 5CT Casing Detail

API 5CT Casing DetailUnder ISO9001, we own a set of complete and effective quality system in our factory. Authorized by the American Petroleum Institute, Anson steel is awarded API 5CT production certificate. Furthermore, we has strict inspection and test system before shipping including dimensional inspection, strength test, tensile test, hardness test, hydrostatic test etc. Therefore, our API 5CT well casing has enough quality assurance to eliminate your worries.

Anson steel as a professional casing pipe suppliers and exporter in casing and tubing as well as drill tubes and drill collars in the international trade, we have enough in stock in the warehouse every month. Furthermore, we keep a good relationship with each big steel factory in China, so we can guarantee the delivery time and competitive prices for customers. Therefore, if you have any inquiry on API 5CT casing, please contact us by e-mail or ring us as soon as possible!

Packing for Well Casing

Packing for Well Casing Well Casing Delivery

Well Casing DeliveryAPI 5CT Well Casing Length:

| API 5CT Casing | Range 1 | Range 2 | Range 3 |

|---|---|---|---|

| 4.88~7.62 | 7.62~10.36 | 10.36~14.63 |

API 5CT Well Casing Dimension:

| Labels | OD(mm) | WT(mm) | J55/K55 | N80 | L80 | C90/T95 | P110 | Q125 | |

|---|---|---|---|---|---|---|---|---|---|

| 4 1/2 | 9.5 | 114.3 | 5.21 | PS | - | - | - | - | - |

| 10.5 | 114.3 | 5.69 | PSB | - | - | - | - | - | |

| 11.6 | 114.3 | 6.36 | PSLB | PLB | PLB | PLB | PLB | - | |

| 13.5 | 114.3 | 7.37 | - | PLB | PLB | PLB | PLB | - | |

| 15.1 | 114.3 | 8.56 | - | - | - | - | PLB | PLB | |

| 5 | 11.5 | 127 | 5.59 | PS | - | - | - | - | - |

| 13 | 6.43 | PSLB | - | - | - | - | - | ||

| 15 | 7.52 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

| 18 | 9.19 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

| 21.4 | 11.10 | - | PLB | PLB | PLB | PLB | PLB | ||

| 23.2 | 12.14 | - | PLB | PLB | PLB | PLB | PLB | ||

| 24.1 | 12.7 | - | PLB | PLB | PLB | PLB | PLB | ||

| 5 1/2 | 14 | 139.7 | 6.20 | PS | - | - | - | - | - |

| 15.5 | 6.98 | PSLBE | - | - | - | - | - | ||

| 17 | 7.72 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

| 20 | 9.17 | - | PLBE | PLBE | PLBE | PLBE | - | ||

| 23 | 10.54 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

| 26.8 | 12.7 | - | - | - | P | - | - | ||

| 29.7 | 14.27 | - | - | - | P | - | - | ||

| 32.6 | 15.88 | - | - | - | P | - | - | ||

| 35.3 | 17.45 | - | - | - | P | - | - | ||

| 38 | 19.05 | - | - | - | P | - | - | ||

| 40.5 | 20.62 | - | - | - | P | - | - | ||

| 43.1 | 64.14 | - | - | - | P | - | - | ||

| 6 5/8 | 20 | 168.28 | 7.32 | PSLB | |||||

| 24 | 8.94 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

| 28 | 10.59 | - | PLBE | PLBE | PLBE | PLBE | - | ||

| 32 | 12.06 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

| 7 | 20 | 177.8 | 6.91 | PS | |||||

| 23 | 8.05 | PSLBE | PLBE | PLBE | PLBE | - | - | ||

| 26 | 9.19 | PSLBE | PLBE | PLBE | PLBE | PLBE | - | ||

| 29 | 10.6 | PLBE | PLBE | PLBE | PLBE | ||||

| 32 | 11.51 | PLBE | PLBE | PLBE | PLBE | ||||

| 35 | 12.65 | PLBE | PLBE | PLBE | PLBE | PLBE | |||

| 38 | 13.72 | PLBE | PLBE | PLBE | PLBE | PLBE | |||

| 7 5/8 | 26.4 | 193.67 | 8.33 | PSLBE | PLBE | PLBE | PLBE | - | - |

| 29.7 | 9.52 | - | PLBE | PLBE | PLBE | PLBE | - | ||

| 33.7 | 10.92 | - | PLBE | PLBE | PLBE | PLBE | - | ||

| 39 | 12.7 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

| 42.8 | 14.27 | - | PLB | PLB | PLB | PLB | PLB | ||

| 45.3 | 15.11 | - | PLB | PLB | PLB | PLB | PLB | ||

| 47.1 | 15.88 | - | PLB | PLB | PLB | PLB | PLB | ||

| 8 5/8 | 24 | 219.08 | 6.71 | PS | - | - | - | - | - |

| 28 | 7.72 | - | - | - | - | - | - | ||

| 32 | 8.94 | PSLBE | - | - | - | - | - | ||

| 36 | 10.16 | PSLBE | PLBE | PLBE | PLBE | - | - | ||

| 40 | 11.43 | - | PLBE | PLBE | PLBE | PLBE | - | ||

| 44 | 12.70 | - | PLBE | PLBE | PLBE | PLBE | - | ||

| 49 | 14.15 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

| 9 5/8 | 36 | 244.48 | 8.94 | PSLB | - | - | - | - | - |

| 40 | 10.03 | PSLBE | PLBE | PLBE | PLBE | - | - | ||

| 43.5 | 11.05 | - | PLBE | PLBE | PLBE | PLBE | |||

| 47 | 11.99 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

| 53.5 | 13.84 | - | PLBE | PLBE | PLBE | PLBE | PLBE | ||

| 58.4 | 15.11 | - | PLB | PLB | PLB | PLB | PLB | ||

| 10 3/4 | 40.5 | 273.05 | 8.89 | PSB | - | - | - | - | - |

| 45.5 | 10.16 | PSBE | - | - | - | - | - | ||

| 51 | 11.43 | PSBE | PSBE | PSBE | PSBE | PSBE | - | ||

| 55 | 12.57 | - | PSBE | PSBE | PSBE | PSBE | - | ||

| 60.7 | 13.84 | - | - | - | PSBE | PSBE | PSBE | ||

| 65.7 | 15.11 | - | - | - | PSB | PSB | PSB | ||

| 113/4 | 47 | 298.45 | 9.53 | PSB | - | - | - | - | - |

| 54 | 11.05 | PSB | - | - | - | - | - | ||

| 60 | 12.42 | PSB | PSB | PSB | PSB | PSB | PSB | ||

| 13 3/8 | 48 | 339.72 | 8.38 | - | - | - | - | - | - |

| 54.5 | 9.65 | PSB | - | - | - | - | - | ||

| 61 | 10.92 | PSB | - | - | - | - | |||

| 68 | 12.19 | PSB | PSB | PSB | PSB | PSB | - | ||

| 72 | 13.06 | - | PSB | PSB | PSB | PSB | PSB | ||

| 16 | 75 | 406 | 11.13 | PSB | - | - | - | - | - |

| 84 | 12.57 | PSB | - | - | - | - | - | ||

| 109 | 16.66 | P | P | P | - | P | P | ||

| 20 | 94 | 508 | 11.13 | PSLB | - | - | - | - | - |

| 30 | 96 | 762 | 16.13 | PSLB | - | - | - | - | - |

| P-Plain end; S-Short round thread; L-Long round thread; B-Buttress thread; E-Extreme line; | |||||||||

Mechanical Properties:

| Steel grade | Type | Yield Strength Mpa | Tensile Strength (min) Mpa | Hardness | ||

|---|---|---|---|---|---|---|

| min | max | HRC | HBW | |||

| J55 | - | 379 | 552 | 517 | - | - |

| K55 | - | 379 | 552 | 655 | - | - |

| N80 | 1 | 552 | 758 | 689 | - | - |

| Q | 552 | 758 | 689 | - | - | |

| L80 | 1 | 552 | 655 | 655 | 23 | 241 |

| 9Cr | 552 | 655 | 655 | 23 | 241 | |

| 13Cr | 552 | 655 | 655 | 23 | 241 | |

| C90 | 621 | 724 | 689 | 25.4 | 255 | |

| C95 | - | 655 | 758 | 724 | - | - |

| T95 | 655 | 758 | 724 | 25.4 | 255 | |

| P110 | - | 758 | 965 | 862 | - | - |

| Q125 | All | 862 | 1034 | 931 | - | - |