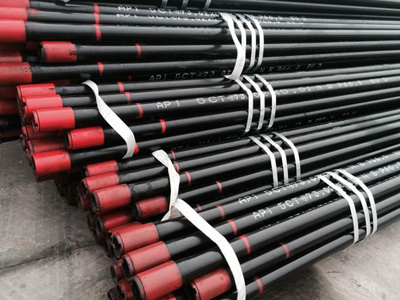

Specifications about API 5CT Tubing

★Standard: API SPEC 5CT

★Grades: J55, K55, N80-1, N80-Q, L80-1, L80-9Cr, L80-1, C90, T95, C95, P110, Q125

★Dimension: OD 48.26-114.3mm; WT 3.18-16mm

★Thread types: NUE, EUE, VAM, special clearance, XC, VAM TOP, NEW VAM

★Application: for extracting oil or gas from wells;

API SPCE 5CT tubing is used to transport crude oil or natural gas from layer of the oil and natural gas to surface. It has better pressure during oil or gas production and smaller diameters.

API 5CT Tubing Production Line

API 5CT Tubing Production Line Oil Tubing Detail

Oil Tubing DetailBecause of API 5CT and ISO 9001 authorized, we have little claims from customers up to now. Just as showing in the quality control, Anson steel has professional testing laboratory and the ability for testing the samples. The experiment includes low and high temperature, impacting, rigidity, fatigue, fracture mechanism, falling weight, metallurgical, stress corrosion and compounds analysis etc. Therefore, choosing octg tubing from Anson steel is best choice with high quality and competitive prices!

Tubing Packing

Tubing Packing Oil Tube Delivery

Oil Tube DeliverySpecifications for API SPEC 5CT Tubing:

| Label | OD (mm) | WT (mm) | Type of End-finish | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NU T&C | EU T&C | IJ | H40 | J55 | L80 | N80 | C90 | T95 | P110 | |||

| 1.9 | 2.75 | 2.9 | 2.76 | 48.26 | 3.68 | PNUI | PNUI | PNUI | PNUI | PNUI | PNUI | - |

| 1.9 | 3.65 | 3.73 | - | 48.26 | 5.08 | PU | PU | PU | PU | PU | PU | PU |

| 1.9 | 4.42 | - | - | 48.26 | 6.35 | - | - | P | - | P | P | - |

| 2 3/8 | 4 | - | - | 60.32 | 4.24 | PU | PN | PN | PN | PN | PN | - |

| 2 3/8 | 4.6 | 4.7 | - | 60.32 | 4.83 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2 3/8 | 5.8 | 5.95 | - | 60.32 | 6.45 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 3/8 | 6.6 | - | - | 60.32 | 7.49 | - | - | P | - | P | P | - |

| 2 3/8 | 7.35 | 7.45 | - | 60.32 | 8.53 | - | - | PU | - | PU | PU | - |

| 2 7/8 | 6.4 | 6.5 | - | 73.02 | 5.51 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 7.8 | 7.9 | - | 73.02 | 7.01 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 8.6 | 8.7 | - | 73.02 | 7.82 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 9.35 | 9.45 | - | 73.02 | 8.64 | - | - | PU | - | PU | PU | - |

| 2 7/8 | 10.5 | - | - | 73.02 | 9.96 | - | - | P | - | P | P | - |

| 3 1/2 | 7.7 | - | - | 88.9 | 5.49 | PN | PN | PN | PN | PN | PN | - |

| 3 1/2 | 9.2 | 9.3 | - | 88.9 | 6.45 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 3 1/2 | 10.2 | - | - | 88.9 | 7.34 | PN | PN | PN | PN | PN | PN | - |

| 3 1/2 | 12.7 | 12.95 | - | 88.9 | 9.52 | - | - | PNU | PNU | PNU | PNU | PNU |

| 3 1/2 | 14.3 | - | - | 88.9 | 10.92 | - | - | P | - | P | P | - |

| 3 1/2 | 15.5 | - | - | 88.9 | 12.09 | - | - | P | - | P | P | - |

| 4 | 9.5 | - | - | 101.6 | 5.74 | PN | PN | PN | PN | PN | PN | - |

| 4 | 10.7 | 11 | - | 101.6 | 6.65 | PU | PU | PU | PU | PU | PU | - |

| 4 | 13.2 | - | - | 101.6 | 8.38 | - | - | P | - | P | P | - |

| 4 | 16.1 | - | - | 101.6 | 10.54 | - | - | P | - | P | P | - |

| 4 1/2 | 12.6 | 12.75 | - | 114.3 | 6.88 | PNU | PNU | PNU | PNU | PNU | PNU | - |

| 4 1/2 | 15.2 | - | - | 114.3 | 8.56 | - | - | P | - | P | P | - |

Mechanical Properties:

| Standard | Steel Grade | Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) | Hardness |

|---|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379~552 | 0.5% | |

| K55 | ≥655 | 379~552 | 0.5% | ||

| N80 | ≥689 | 552~758 | 0.5% | ||

| L80(13Cr) | ≥655 | 552~655 | 0.5% | ≤241HB | |

| P110 | ≥862 | 758~965 | 0.6% |

Chemical Compositions(%):

| Standard | Steel Grade | Chemical Compositions(%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V | Als | ||

| API SPEC 5CT | J55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | ≤0.020 |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | ≤0.020 | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | ≤0.020 | |

| L80(13Cr) | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | ≤0.020 | |

| P110 | 0.26~0.35 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | ≤0.020 | |